On-site PSA Nitrogen Plants

Absolut Air has designed, engineered, manufactured and operated on-site gas generation systems for over 20 years, and has created an outstanding global product line. Our low cost, customized nitrogen solutions offer the best value in gas industry.

Absolut Air proprietary Nitrogen Pressure Swing Adsorption (PSA) Systems offers highly reliable, low cost, customized nitrogen solutions with savings of up to 80% over traditional bottles.

Each system is customized to suit client’s flow, purity, pressure and dew point requirements as per the application. These extremely cost-effective nitrogen systems feature a proprietary adsorption process developed by Absolut.

The standard and high purity equipment range offers flow rates of up to 2500 Nm3/hr and nitrogen purities up to 99.9999%.

Nitrogen Plants from Absolut Air – a system to suit every application

Understanding that every application and location is unique, Absolut Air PSA Nitrogen Systems offers a family of Standard and High purity Nitrogen Solutions, to meet the most stringent flow, purity and pressure requirements.

For each model, the type of molecular sieve, the compressor frame size, the operational cycle, and other internal process parameters can be optimised to meet your specifications for flow, purity, and pressure.

Engineered for on-site operation, Absolut Air PSA Nitrogen Systems can also be configured with advanced SCADA and telemetry capabilities for remote monitoring.

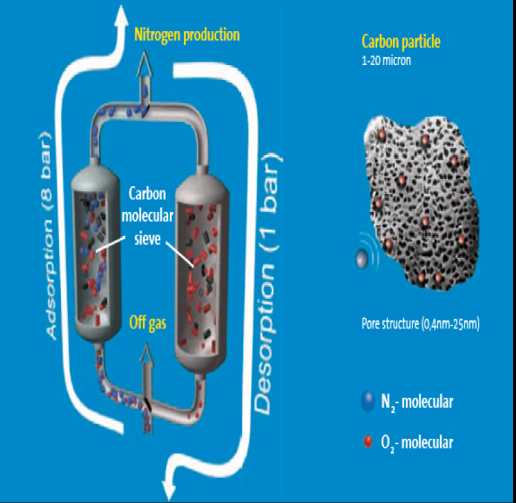

Technology at Work – How nitrogen is produced

In the unique PSA cycle, oxygen, moisture, and carbon dioxide are removed from air through use of a molecular sieve to produce nitrogen gas with maximum efficiency.

When compressed and purified air is passed on a bed of carbon molecular sieve, mainly oxygen is adsorbed on its surface, and nitrogen enriched gas leaves the tower. During adsorption in one tower the second tower is totally regenerated by depressurization to ambient pressure. The nitrogen purity delivered range between 95% and 99.99%.

After about one-minute of adsorption, the micro-processor in the control panel automatically directs the flow of air to another tower by sequencing the changeover valves.

Absolut has access to the latest grade of Carbon Molecular Sieves from Carbotech GmbH, Germany, or Kuraray, Japan, used for such nitrogen production. These companies, provide us the latest grade of molecular sieves and technical back ups with regards to the design and optimizing efficiencies based on the actual ambient conditions.

Absolut Air Nitrogen On-site systems meet the most stringent flow, purity and pressure requirements. Our low cost, customized nitrogen solutions offer the best value in gas industry. As a leading innovator of adsorption technologies Absolut has hundreds of Nitrogen PSA Systems in operation around the clock.

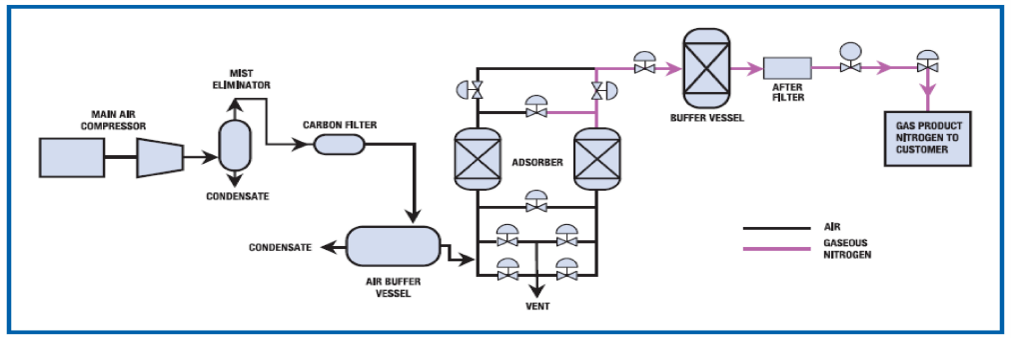

The PSA process

The standard PSA system is comprised of four major operations: Feed Air Compression; Feed Air Pre-treatment; Adsorption/Desorption; Product Delivery.

01. Feed Air Compression

Atmospheric air is elevated to high pressure by a packaged air compressor.

03. PSA Adsorption/Desorption Skid

The treated air enters an adsorption tower where it is contacted with carbon molecular sieve to remove oxygen. Purified nitrogen passes to product delivery operation.

When the oxygen capturing capacity of† the onstream adsorption tower is diminished, the feed flow process valves switch to a second adsorption tower. The first adsorption tower is then depressurised rapidly and purged to remove the adsorbed oxygen. When the second bed becomes saturated with oxygen, the feed flow process valves switch back to the first adsorption tower and the cycle begins again.

02. Feed Air Pre-Treatment

The high-pressure feed air from the compressor passes through a mist eliminator to remove water droplets and entrained oil. The air then passes through the carbon filter to remove oil vapours prior to entering the air buffer vessel.

04. Product Delivery

The purified nitrogen enters a nitrogen receiver tank that provides gas to the adsorber vessels. During product re- pressurisation and nitrogen buffer capacity. The nitrogen purity is continuously monitored by an oxygen analyser prior to delivery to the customer houseline. Should the oxygen level rise above the pre-set alarm point, the product delivery valves isolate any off-specification product from the customer houseline. The system will automatically enter a clean-up mode and product delivery will resume when the nitrogen purity is within specification. A flow control system prevents system overdraw

Plant General Specifications

Absolut Air provides following boundary conditions to on-site Nitrogen Solutions:

| Flow Rates | Purity | Oxygen | Pressure |

|---|---|---|---|

| 5 to 2500 Nm3/hr | 95% to 99.9999% | 50000 PPM to 1 PPM | 4 to 50 Kg/cm2g |

| Atm. Dew Point | Temperature | Air Quality | Power |

|---|---|---|---|

| (-) 40 up to (-) 100 Deg C | Ambient | ISO 8573 - 2010 class 1-4-1 | 415 V, 3 Phase, 50 Hz |

| Specific Power | Air Compressors | Electricals | Noise Levels |

|---|---|---|---|

| From 0.3 kWh/Nm3 (99%) to 0.5 kWh/Nm3 (99.99%) | Generally designed as per manufacturer standard, unless specified | Standard wiring and controls, as per international industrial standards | 80 dBA time weighted average at 1 meter, in free field area. |

| Quality | Pressure Piping | Pressure Vessels |

|---|---|---|

| Absolut Air meets ISO 9001, and follows established engineering procedures. | Conforms with ANSI B3.1.1, Schedule 40, Fittings as per ANSI B16.9; Flanges as per ANSI B16.5. Other codes satisfied if required. | Designed and fabricated as per ASME Sec VIII Div I. |

High Purity Nitrogen Plants

For ultra high purity nitrogen, Absolut Air offer customized solutions.

First, the raw nitrogen is produced from PSA process, then is purified in a catalytic reduction, followed by thermally regenerative gas dryer, so as to produce 99.9999% nitrogen, with specific power as low as 0.35 kWh/Nm3.

Various options available

- Nitrogen booster for high pressure storage and/or use.

- Air compressor and air tank part of standard accessories.

- Dual oxygen analysers and Moisture Meters.

- Vortex Flow Transmitters / Mass Flowmeters.

- Complete SCADA solutions for Data Acquisition.

- Remote monitoring via telemetry or analog signals.

- Complete annual after-service maintenance agreements.

Safe & Healthy Environment

Absolut Air believe that nothing is more important than safety. We have extensive Safety Management systems, procedures and detailed engineering standards, as well as more than 25 years of plant operation experience.

This expertise is applied to all plants and equipment that Absolut Air operates and sells, to ensure the safety of employees, customers and general community.

Absolut Air PSA Nitrogen Plant Features

- Our diverse product line can achieve Oxygen content from 50,000 down to 5 ppm.

- Purifiers achieve oxygen in nitrogen to 1 PPM levels.

- Few moving parts and simple engineering.

- Allows quick equipment startup and stop.

- Environmentally friendly.

- Meets international standards.

- Compact footprint.

- Economiser shutdown.

- Integral Sound abatement.

- Exclusive stayfill bed containment.

- Microprocessor-control system allows unattended operation and maintains highest efficiency.

- Remote monitoring telemetry system available on optional basis.

Plant Benefits

- Can be installed in remotest of areas as electrical power is only the raw material required.

- Liquid Nitrogen purity with flexibility and cost savings.

- Provides savings of up to 80% over bottles mode.

- The investment pays back in a few months time.

- Minimal maintenance and maximum reliability.

- Unattended operation with highest efficiency.

- Saves energy during periods of low demand.

- Safe operation as low pressures involved.