On-site PSA Medical Oxygen Plants

Generate your own medical oxygen on-site

Medical Oxygen by PSA, a unique solution ; with certified quality.

The modular skid mounted Medical Oxygen Concentrators from apply the Pressure Swing Adsorption (PSA) process for the on-site production of medical oxygen from clean compressed air.

Each such unit conforms to the Oxygen 93% Monograph of the European and US Pharmacopoeia.

The design offer you unique features to overcome the major disadvantages over the conventional medical oxygen supply mode of cylinder bottles and liquid oxygen tanks.

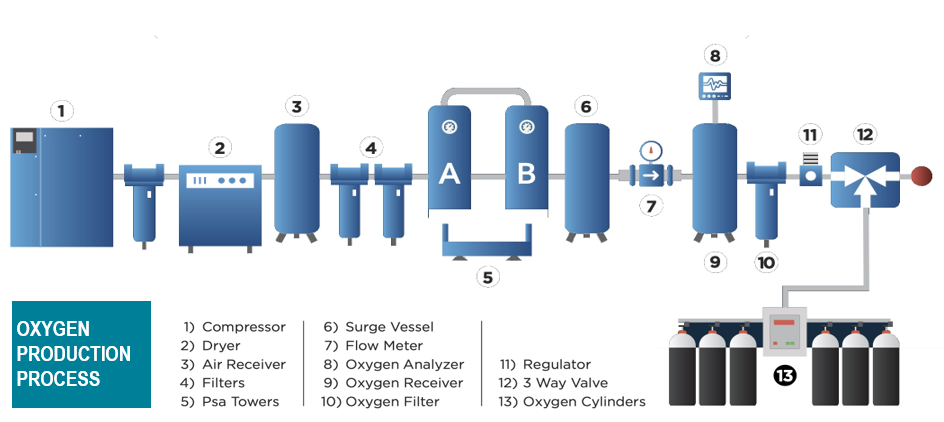

A PSA (Pressure Swing Adsorption) Oxygen Plant works on separation of oxygen molecules from air. Clean Dry compressed air is generated and fed to the PSA adsorber beds, by the Air Compressor followed by a Refrigerated Dryer with series of filters. The PSA adsorber beds are filled with special grade of Zeolite Molecular Sieves (ZMS).

When compressed and purified air is passed on a bed of zeolite molecular sieve, mainly nitrogen is adsorbed on its surface, and oxygen enriched gas leaves the tower. During adsorption in one tower the second tower is totally regenerated by depressurization to ambient pressure. The nitrogen enriched off gas is vented to atmosphere. The microprocessor in the control panel automatically directs the flow of air to another tower by sequencing the changeover valves. The oxygen purity of 93% is delivered as a minimum on continuous basis.

Complying to International Standards

- Conforms to United States Pharmacopeia (USP) XXI Oxygen 93% Monograph.

- The plant fabricated in accordance with all relevant codes (ASME, ANSI, NEMA, CE)

- Plant configured to meet ISO 10083 and CSA Z 305.6-92 standards.

Selection of Medical Oxygen Plant

| Model | Recommended for Hospital Beds | Recommended Medical Oxygen Flow | Equivalent O2 Cylinders | Power Required | O2 Receiver Size | Area Required | |

|---|---|---|---|---|---|---|---|

| No | LPM | Nm3/hr | No/Day | KW | Litres | M (L x B x H) | |

| AMO 100 | 20-25 | 100 | 6 | 20 | 12.5 | 1500 | 5 x 4 x 3 |

| AMO 150 | 25-40 | 150 | 9 | 30 | 16.5 | 2000 | 6 x 4 x 3.5 |

| AMO 200 | 50-60 | 200 | 12 | 40 | 20 | 2500 | 6 x 4 x 3.5 |

| AMO 300 | 70-80 | 300 | 18 | 60 | 32 | 3000 | 7 x 5 x 3.5 |

| AMO 400 | 80-100 | 400 | 24 | 80 | 40 | 4000 | 7 x 5 x 3.5 |

| AMO 500 | 100-150 | 500 | 30 | 100 | 48 | 5000 | 8 x 5 x 4 |

| AMO 700 | 150-175 | 700 | 42 | 140 | 58 | 5000 | 8 x 5 x 4 |

| AMO 850 | 175-225 | 850 | 50 | 170 | 80 | 8000 | 10 x 5 x 4.5 |

| AMO 1000 | 250-300 | 1000 | 60 | 200 | 95 | 10000 | 12 x 6 x 4.5 |

*Please contact us for higher models required than above

Suggested Guidelines for Hospitals

Capacity= (1 x No. of beds + No. of beds in ICU x 10 + No. of beds in operation theatre x 10) (LPM)

General Specifications

| Oxygen Purity - 93±3%. | Oxygen Pressure - 4 - 5 bar a. | Oxygen Temperature - 40-45 Deg C |

| Air pressure - 7 bar g. | Air quality - ISO 8573 - 2010 class 1-4-1 | Power - 415 V, 3 Phase, 50 Hz. |

Features and Benefits

- Oxygen anytime - eliminates cylinder or liquid oxygen availability issues; i.e., zero dependency on external sources.

- Oxygen on demand - power as only requirement, can be installed at any remote location.

- Safe – eliminates safety risk associated with handling high pressure cylinders and liquid oxygen.

- Economical – Low operating costs than other modes.

- Fast pay-back – as low as less than one year.

- Reliable – can be provided with 100% redundancy.

- Convenience - Fully Automatic and unattended operation.

- Eliminate – oxygen logistics issues and purchase cycles.

- On-line check- gas sensors to check oxygen purity.

- Filters - Bacteria filters part of standard supply.

- Automation - total automation with SCADA features.

- Oxygen concentration as per US Pharmacopeia (USP) XXI Oxygen 93% Monograph, totally safe for medical use.

- Option to add cylinder filling station.